Dynamometer Test System

There are 4 various dynamometer systems

Take the servo motor as a load - AC/DC Motor Testing

Take hysteresis, eddy current, or powder as a load

Use the unique application of Prony braking to measure stepper motors and micromotors

Cogging Torque Test System

Choose the appropriate configuration according to your needs, and get the highest C/P value

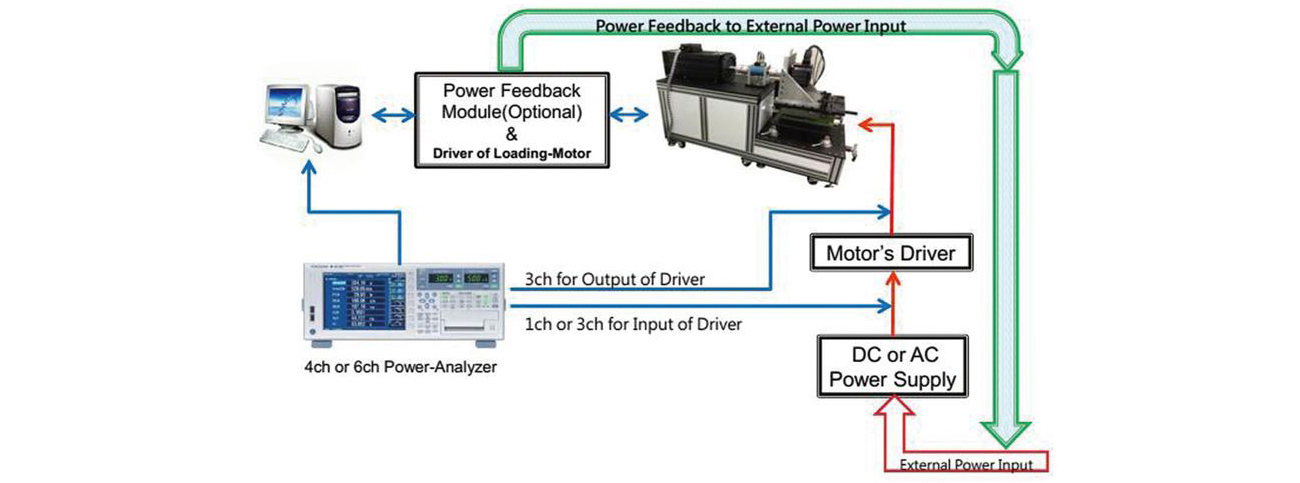

Dynamometer Test System (With Servomotor as a load)

Applicable Motor Type:

- BLDC motor

- AC/ DC servo motor

- Single/ Three-phase induction motor

- Single/ Three-phase induction compressor motor

- DC Brushless compressor motor

Hardwares:

- Load Part:

- Servomotor

- Power Feedback module (optional)

- Measurement Part:

- Torque Meter:

Kistler brand or Magtrol brand - Power Analyzer:

Yokogawa brand WT series

Hioki brand WP series - Low-Resistance meter: Hioki brand RM3544-01

- Computer: Advantech Industrial Computer

- Torque Meter:

Test items:

- 1 ψ Induction motor ==» V, A of the Main-Line, Vice-Line and Capacitor, and ∑ W

- 3 ψ Induction motor ==» Each phase V, A, and ∑ W

- Simultaneously measuring each phase V, A, and ∑ W of input and output of the driver.

- Torque, Speed, Motor- Efficiency, Drive-Efficiency, Total-Efficiency, Motor-housing Temperature (Optional), Motor-coil Temperature (Optional), Ld & Lq (Optional), Back EMF (Optional), and so on.

Software functions:

- With the inertia compensation function

- Motor-File management: Add, Edit, Delete, Quick Search, Copy, and other functions

- Data-File management: Add, Edit, Delete, Quick Search, Copy, Print, and other functions

- T-N Characteristic-Curve test & Fixed-Point test & Manual test

- Data-File can be exported to Excel format

- Test data can be displayed in 6 independent curves

- Characteristic-Curve can be used for comparison

(5 curves of characteristics can be drawn on the same screen)

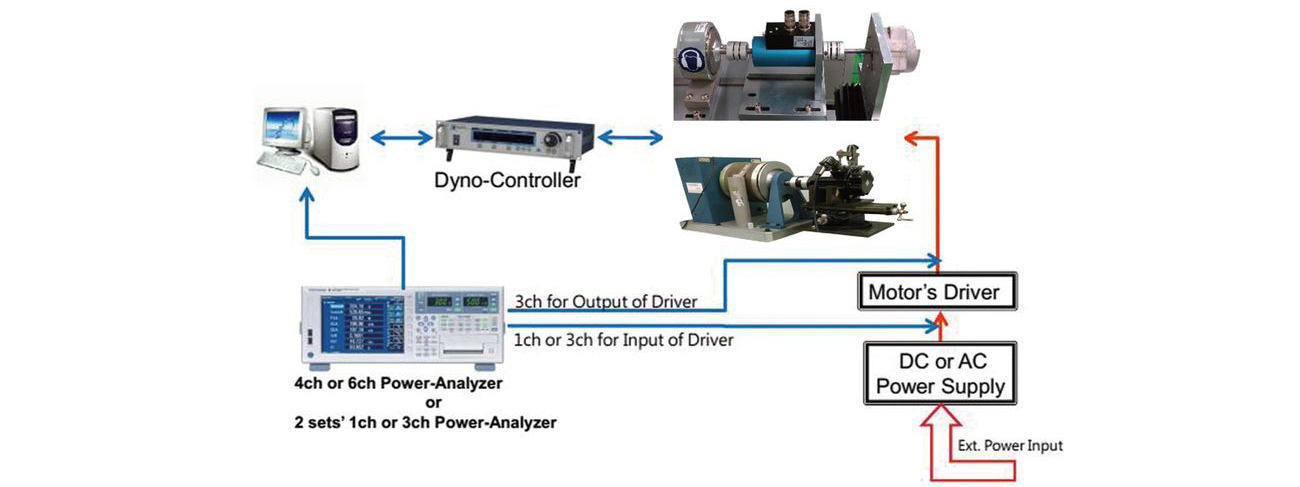

Dynamometer System (With hysteresis or eddy-current or powder as a load)

Applicable Motor Type:

- BLDC motor

- AC/ DC servo motor

- Single/ Three-phase induction motor

- High-Speed and High-Power motor (With Eddy-Current Loading)

- Low-Speed and High-Power motor (With Powder Loading)

Hardware:

- Load Part:

Using Hysteresis or Eddy-Current or Powder - Measurement Part:

- Torque Meter:

Kistler brand or Magtrol brand - Power Analyzer:

Yokogawa brand WT series

Hioki brand PW series

Magtrol brand - Low-Resistance meter: Hioki brand RM3544-01

- Dyno-Controller:

Join-Precision brand DC-1000 or DC-2000

Magtrol brand DSP series - Computer: Advantech Industrial Computer

- Torque Meter:

Test items:

- 1 ψ Induction motor ==» V, A of the Main-Line, Vice-Line and Capacitor, and ∑ W

- 3 ψ Induction motor ==» Each phase V, A, and ∑ W

- Simultaneously measuring each phase V, A, and ∑ W of input and output of the driver.

- Torque, Speed, Motor- Efficiency, Drive-Efficiency, Total-Efficiency, Motor-housing Temperature (Optional), Motor-coil Temperature (Optional), and so on.

Software functions:

- With the inertia compensation function

- Motor-File management: Add, Edit, Delete, Quick Search, Copy, and other functions

- Data-File management: Add, Edit, Delete, Quick Search, Copy, Print, and Feature Chart Printing and other functions

- T-N Characteristic-Curve test & Fixed-Point test & Manual test

- Data-File can be exported to Excel format

- Test data can be displayed in 6 independent curves

- Characteristic-Curve can be used for comparison

(5 curves of characteristics can be drawn on the same screen)

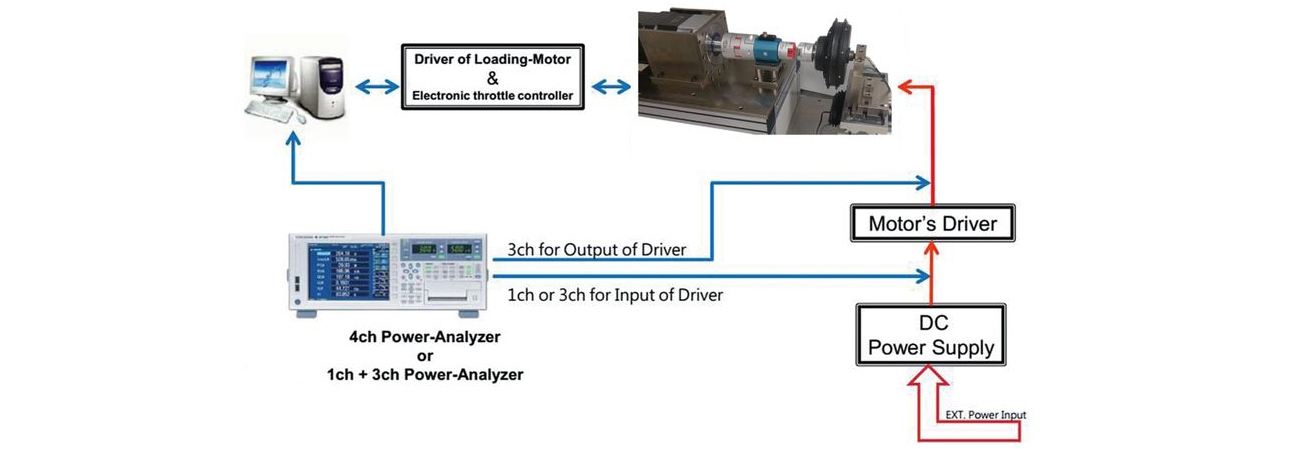

Hub Motor Test System

Hardware:

- Load Part:

- Take a Servomotor or a Powder Brake

- Power Feedback module (optional)

- Measurement Part:

- Torque Meter:

Kistler brand or Magtrol brand - Power Analyzer:

Yokogawa brand WT series

Hioki brand PW series - Low-Resistance meter: Hioki brand RM3544-01

- Computer: Advantech Industrial Computer

- Torque Meter:

Test items:

- Simultaneously measuring each phase V, A, and Z W of input and output of the driver.

- Torque, Speed, Motor- Efficiency, Drive-Efficiency, Total-Efficiency, Motor-housing Temperature (Optional), Motor-coil Temperature (Optional), Ld & Lq (Optional), Back EMF (Optional) ... and so on.

Software functions:

- Providing the simulated electronic throttle control voltage for the DUT

- Motor-File management: Add, Edit, Delete, Quick Search, Copy, and other functions

- Data-File management: Add, Edit, Delete, Quick Search, Copy, Print, and other functions

- T-N Characteristic-Curve test & Fixed-Point test & Manual test & Road simulation & Life test

- Data-File can be exported to Excel format

- Test data can be displayed in 6 independent curves

- Characteristic-Curve can be used for comparison

(5 curves of characteristics can be drawn on the same screen)

Stepper Motor Test System

Load-Sensor & Pulley Specifications:

| Model | Load Sensor | Pulley Radius (mm) | ||||

|---|---|---|---|---|---|---|

| Directly wound on the shaft*1 |

2.5mm | 5mm | 10mm | 20mm | ||

| JP-R5N | 0.5N | - | 1.25mNm | 2.5mNm | 5mNm | 10mNm |

| JP-1N | 1N | - | 2.5mNm | 5mNm | 10mNm | 20mNm |

| JP-2N | 2N | - | 5mNm | 10mNm | 20mNm | 40mNm |

| JP-5N | 5N | - | 12.5mNm | 25mNm | 50mNm | 100mNm |

| JP-10N | 10N | - | 25mNm | 50mNm | 100mNm | 200mNm |

| JP-20N | 20N | - | 50mNm | 100mNm | 200mNm | 400mNm |

Torque = Load-Sensor Rating(N) × Pulley Radius(mm)

*1: Torque will be related to motor shaft Radius.

*1: Torque will be related to motor shaft Radius.

Profile:

With the unique application of Prony (winding) braking.

It automatically obtains the full pull-in and pull-out torque curves with high accuracy.

- Pull-in torque:

The maximum torque at which the motor can start from the holding state without losing steps for a given speed - Pull-out torque:

The maximum torque at which the motor can operate without losing steps for a given loading

Advantages:

- Minimal moment of inertia of the tester:

By using the Prony method, the measurement is not affected by the inertia and the coupling loss of the test system. Especially in the Pull-in test, more to show this advantage. - Wide Measuring Range:

Six modes of sensor, to select the proper sensor and pulley,

The measuring Range is from 0.1 to 400 mNm. - Monitoring and analysis easier:

Real-time display of testing results on the screen.

Data-File can be exported to Excel format.

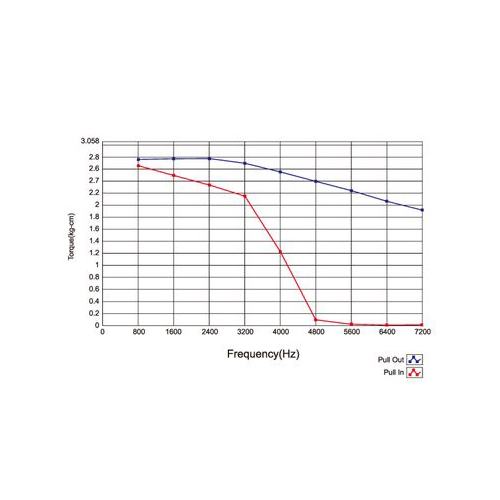

Measured Example:

- Pull-in & Pull-out Curve

- (X-axis: Frequency Y-axis: Torque)

Specifications:

| Brake | Prony braking |

|---|---|

| Load-Sensor | Six types: 0.5N, 1N, 2N, 5N, 10N, 20N |

| Sensor sensitivity | DC 2 V/ rating |

| Torque precision | Within ± 1% of torque range |

| Maximum allowable load | 200% of Sensor rating |

| Torque meas. range | T=Sensor Rating X Pulley Diameter/ 2 |

| Drive frequency range | 16-50,000 Hz |

| Drive signals | Square wave (duty 1:1), TTL-level voltage signal or open-collector signal |

| Operating System | Microsoft Windows |

| Power supply | Single-phase AC100-120V ± 10%,50/ 60 Hz |

| Single-phase AC200-240V ± 10%,50/ 60 Hz |

Tiny Motor Dynamometer Test System

Load-Sensor & Pulley Specifications:

| Model | Load Sensor | Pulley Radius (mm) | ||||

|---|---|---|---|---|---|---|

| Directly wound on the shaft *1 |

2.5mm | 5mm | 10mm | 20mm | ||

| JP-R5N | 0.5N | - | 1.25mNm | 2.5mNm | 5mNm | 10mNm |

| JP-1N | 1N | - | 2.5mNm | 5mNm | 10mNm | 20mNm |

| JP-2N | 2N | - | 5mNm | 10mNm | 20mNm | 40mNm |

| JP-5N | 5N | - | 12.5mNm | 25mNm | 50mNm | 100mNm |

| JP-10N | 10N | - | 25mNm | 50mNm | 100mNm | 200mNm |

| JP-20N | 20N | - | 50mNm | 100mNm | 200mNm | 400mNm |

Torque = Load-Sensor Rating(N) × Pulley Radius(mm)

*1: Torque will be related to motor shaft Radius.

*1: Torque will be related to motor shaft Radius.

Profile:

Adopting the unique Prony (winding) braking technology,

It is available to measure high-precision T-N curve

Advantages:

- No inertia & No coupling loss:

Due to using the Prony method, there are no inertial forces and coupling losses during the test. They are crucial that affecting the accuracy of the testing of micro motors. - Wide Measuring Range:

Six modes of the sensor, to select the proper sensor and pulley

The measuring Range is from 0.1 to 400 mNm. - Monitoring and analysis easier:

Real-time display of the testing results on the screen.

Data-File can be exported to Excel format. - High Speed:

The Max. Speed up to 60,000rpm - Add a power analyzer and you can measure V/A/W and the efficiency of the motor.

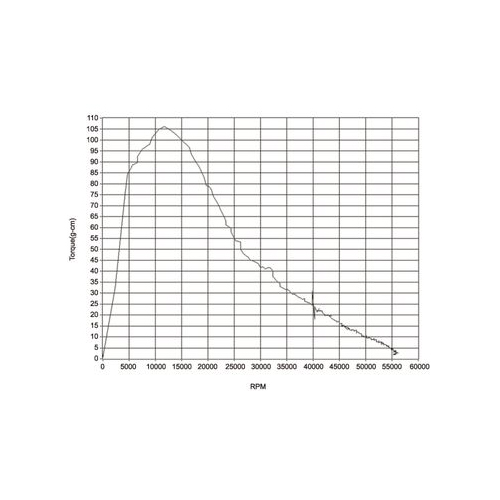

Measured Example:

(X-axis:Speed / Y-axis:Torque)

Specifications:

| Brake | Prony braking |

|---|---|

| Load-Sensor | Six types:0.5N, 1N, 2N, 5N, 10N, 20N |

| Sensor sensitivity | DC 2 V/ rating |

| Torque precision | Within ± 1% of torque range |

| Maximum allowable load | 200% of Sensor rating |

| Torque meas. range | T=Sensor Rating X Pulley Diameter/ 2 |

| Operating System | Microsoft Windows |

| Power supply | Single-phase AC100-120V ± 10%,50/ 60 Hz |

| Single-phase AC200-240V ± 10%,50/ 60 Hz |

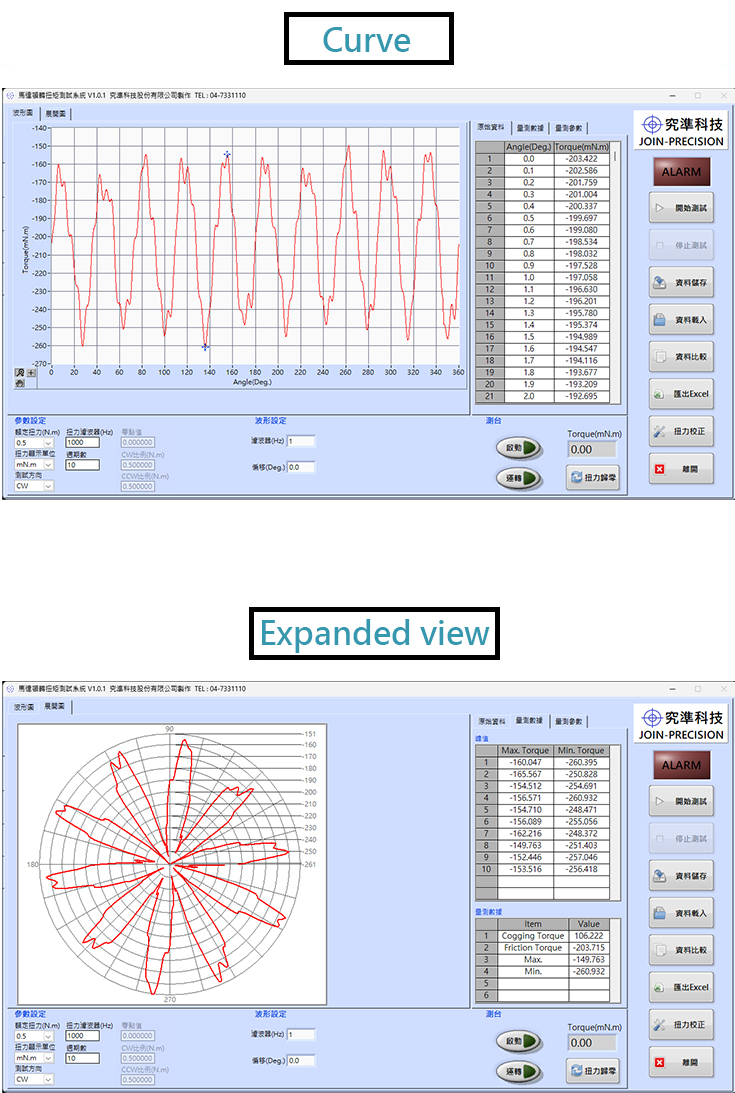

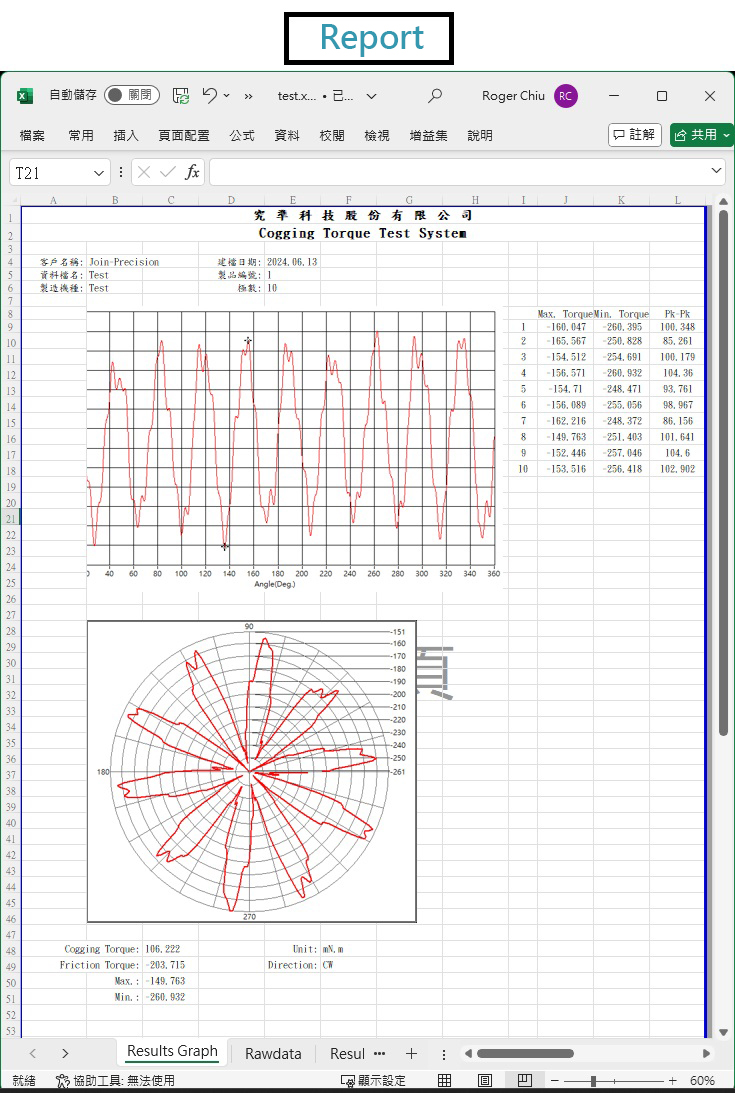

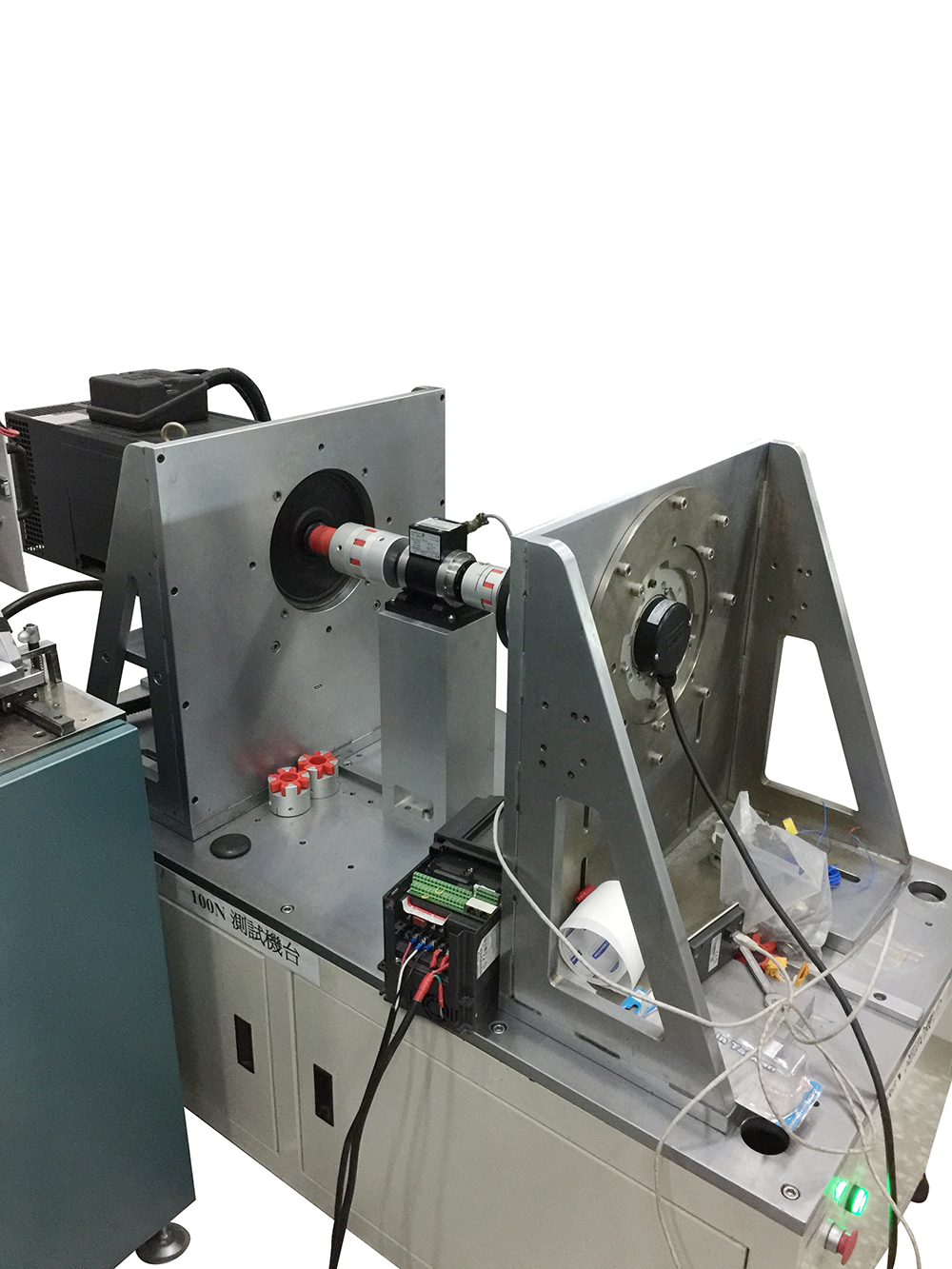

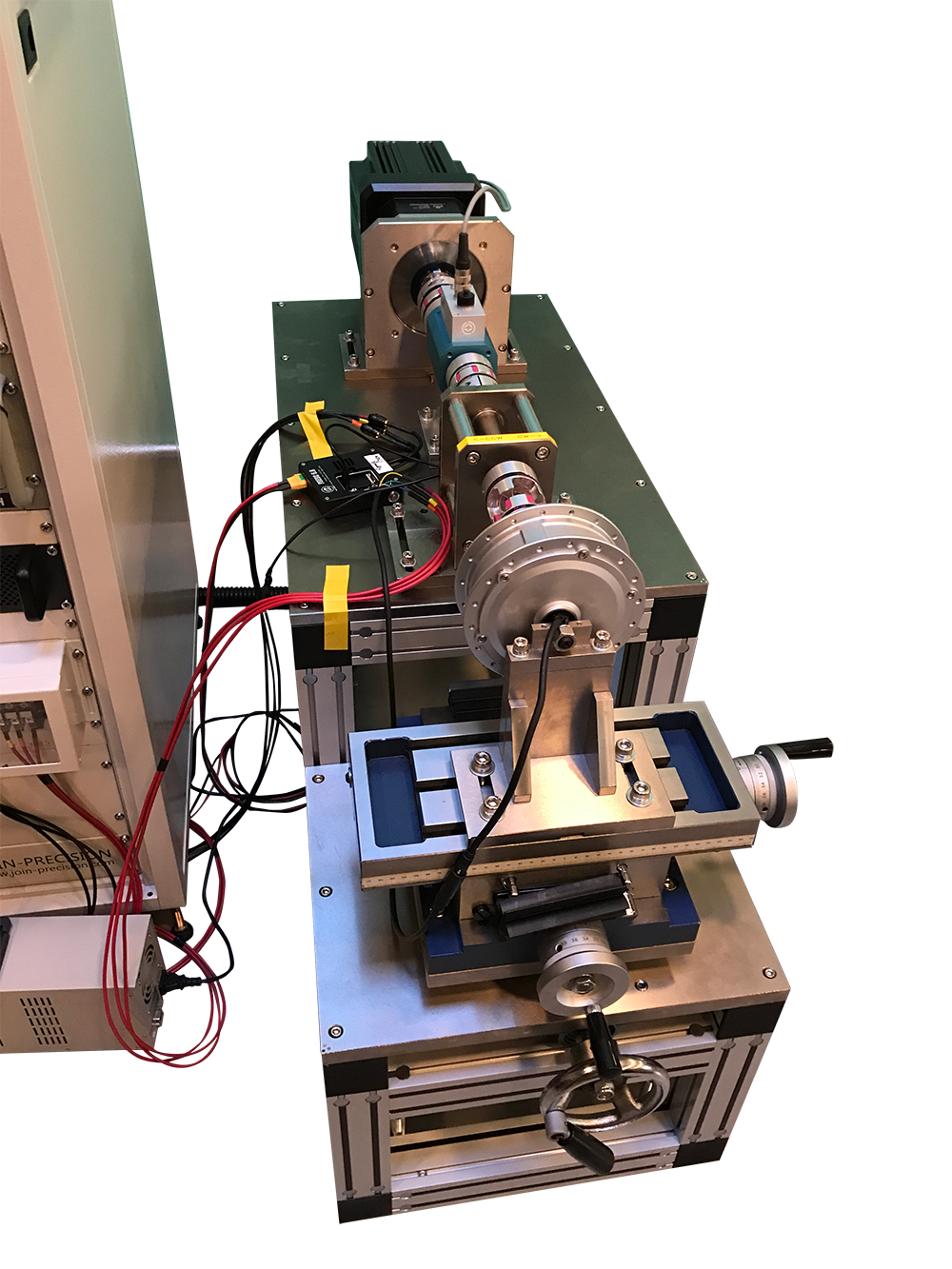

Cogging Torque Test System

The pictures are for reference only

The pictures are for reference only- The torque value is measured by a well-known European brand, and the Japanese high-precision "stepper motor" is used for the drive part

- Measurement range: 20mNm~2Nm (according to the specifications of the torque meter).

- Precision test bench: customized according to motor specifications

- Data capture: 3,600 per lap

- Test items: Cogging Torque, Friction Torque, Torque (Max.), Torque (Min.).

- Others: Curve comparison function